Slave to the Game

Online Gaming Community

ALL WORLD WARS

DESCRIPTION OF THE Colt's DOUBLE-ACTION REVOLVER

CALIBER 45,

MODEL OF 1909

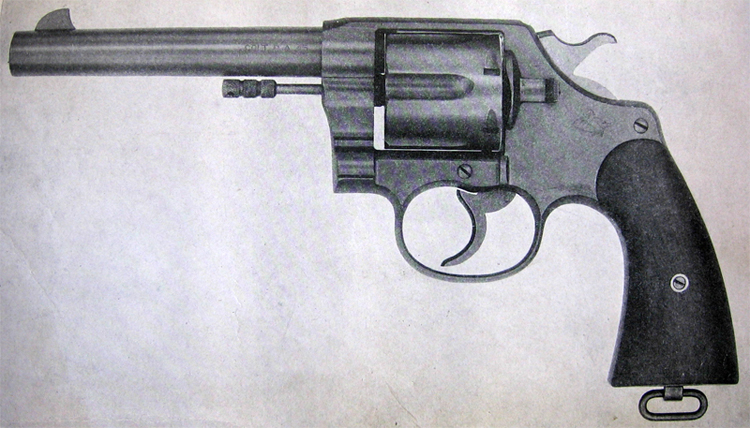

Plate 1. Side view of the revolver

No. 1927

DESCRIPTION OF THE Colt's Double-Action Revolver

CALIBER 45

MODEL OF 1909

WITH RULES FOR MANAGEMENT, MEMORANDA OF TRAJECTORY, AND DESCRIPTION OF AMMUNITION

SEPTEMBER 10, 1909. REVISED JUNE 30, 1913

WAR DEPARTMENT, OFFICE OF THE CHIEF OF ORDNANCE

Washington, June 30, 1913.

This manual is published for the information and government of the Regular Army and Organized Militia of the United States.

By order of the Secretary of War:

R. BIRNIE,

Colonel, Ordnance Department,

Acting Chief of Ordnance.

DESCRIPTION OF COLT'S DOUBLE-ACTION REVOLVER, CALIBER .45.

The Colt's double-action revolvers, caliber .45, in service are marked «U. S. Army model, 1909."

COMPONENT PARTS

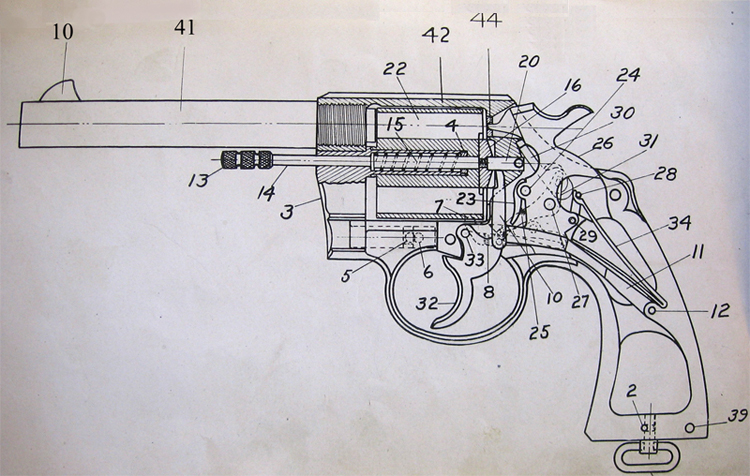

Plate II. Revolver with the side plate and stock removed

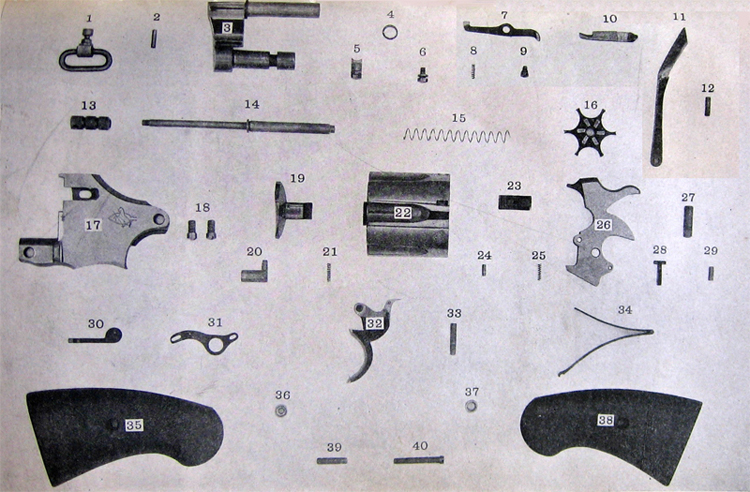

Plate III. Component parts

1. Butt swivel.

2. Butt-swivel pin.

3. Crane.

4. Crane bushing.

5. Crane lock.

6. Crane-lock screw.

7. Cylinder bolt.

8. Cylinder-bolt spring.

9. Cylinder-bolt screw.

10. Hand.

11. Rebound lever.

12. Rebound-lever pin.

13. Ejector-rod head.

14. Ejector rod.

15. Ejector spring.

16. Ejector and ratchet.

17. Side plate.

18. Side-plate screws (2).

19. Latch.

20. Latch pin.

21. Latch spring.

22. Cylinder.

23. Hammer strut. Screw-driver.

24. Hammer-strut pin.

25. Hammer-strut spring.

26. Hammer, firing pin, and firing-pin rivet.

27. Hammer pin.

28. Hammer stirrup.

29. Hammer-stirrup pin.

30. Safety.

31. Safety lever.

32. Trigger.

33. Trigger pin.

34. Mainspring.

35. Stock, right.

36. Escutcheon, threaded.

37. Escutcheon, plan.

38. Stock, left.

39. Stock pin.

40. Stock screw.

41. Barrel.

42. Frame.

43. Front sight.

44. Recoil plate. Screw driver.

OPERATION OF THE PARTS

Plate I is a side view of the revolver.

Plate II shows the revolver with the side plate and stock removed, and with cylinder and other parts cross sectioned to show construction.

Plate III shows the component parts, except the barrel, sight, and frame.

In the plates, parts are given the same numbers as in the list of component parts and in the description that follows.

The barrel (41) is firmly screwed to the frame (42). The bore is .445 men. The front sight (43) is brazed on the barrel. The rear sight is merely a longitudinal groove in the upper surface of the frame.

The lock mechanism is contained in the frame and consists of the hammer (26) with its stirrup (28), stirrup pin (29), strut (23), strut pin (24), and strut spring (25); the trigger (32) with its pin (33), the rebound lever (11); the hand (10); the cylinder bolt (7) with its spring (8); the mainspring (34), which also serves as a rebound-lever spring, hand spring, and trigger spring; the safety (30) and safety lever (31).

The hammer (26) and trigger (32) are pivoted on their respective pins, which are fastened in the right side of the frame (42). The rebound lever (11) is pivoted on its pin (12) within grip of the frame. The lower end of the mainspring (34) fits into a slot in the frame, and its upper end engages the hammer stirrup (28).

The lower arm of the mainspring (34) bears on the upper surface of the rebound lever (11), so that the latter, when the trigger (32) is released after firing a shot, carries the hammer back to its safety position and forces the trigger forward, bringing the hand back to its forward and lowest position. The safety lever (31) being pinned to the trigger (32) by this same motion moves the safety (30) upward in front of the hammer (26).

The revolver may be used either single action or double action. In firing double action, pressure upon the trigger (32) causes its upper edge to engage the hammer strut (23) and thereby raises the hammer (26) until nearly in full-cock position, when the strut will escape from the trigger, and the hammer, under action of the main-spring (34), will fall and strike the cartridge. In firing single action, the hammer (26) is first pulled back with the thumb until the upper edge of the trigger (32) engages in the full-cock notch in the front and of the lower part of the hammer. Pressure on the trigger will release the hammer, which, under the action of the mainspring (34), will fall and strike the cartridge.

The cylinder bolt (7) is pivoted on its screw (9), which is supported on right side of frame. The cylinder-bolt spring (8) pressing upward causes the nose of the bolt (7) to project through a slot in the frame ready to enter one of the rectangular cuts in the surface of the cylinder (22). During the first part of the movement of the trigger (32) in cocking the revolver, the nose of the bolt is withdrawn from the cylinder by rear end of bolt coming in contact with lug on rebound lever, permitting the rotation thereof. The object of the cylinder bolt is to hold the firing chamber in line with the barrel, and also to prevent the cylinder making more than one-sixth of a revolution at the time of cocking.

The hand (10) is attached by its pivot to the trigger, and as the latter swings on its pin when the hammer is being cocked, the hand raised, revolves the cylinder, and serves with the bolt (7) to lock the cylinder in proper position at time of firing, i.e., the axis of the chamber containing cartridge to be fired coinciding with the axis of the bore of the barrel. The pressure of the rebound lever (11) on the lug on the hand insures the engagement of the hand with the ratchet.

The cylinder (22) has six chambers. It revolves around and is supported on a central arbor of the crane (3). The crane fits into a recess in the frame below the barrel and turns on its pivot arm, which rotates in a hole in that part of the frame below the opening for the cylinder, and is secured by the crane lock (5) and crane-lock screw (6). The ejector rod (14) passes through the center of the arbor of the crane supporting the cylinder, and, projecting under the barrel, is terminated by the ejector-rod head (13). The ejector (16), of which the ratchet forms a part, is screwed on the rear end of the ejector rod with a right-handed thread and then firmly secured by upsetting the end of the rod. The ejector spring (15) is coiled around the ejector rod within the cylinder arbor of the crane, the front end bearing on a shoulder of the rod and the rear end on tie crane bushing (4), which is screwed with a right-handed thread into and closes the cylinder arbor.

The latch slides longitudinally on the left side of the side plate and is connected to the latch pin (20) by latch-pin stud, causing it to follow the movement of the latch thumb piece. The latch pin slides in a hole in the frame, and when the cylinder is swung into the frame, the latch pin, under action of the latch spring (21), is forced into a recess in the ejector and locks the cylinder in position for firing. The latch spring (21) is contained in a hole in the side plate in the rear of the latch slot. The recoil plate (44) is driven into its recess in the frame and secured therein by slightly upsetting the rim.

To Eject the Shells and Load.

To eject the shells and load, push the latch to the rear and swing the cylinder to the left out of the frame; pressure against the front end of the ejector-rod head will empty the chambers, and the cylinder is then ready to be loaded; swing the cylinder into the frame, taking care that it is revolved so that the cylinder bolt will enter one of the rectangular cuts in its surface.

To Dismount and Assemble Revolver.

To dismount the revolver, remove the parts in the following order: Grane-lock screw (6) and crane lock (5); crane (3) with cylinder (22); stock crew (40); stocks (35 and 38); side-plate screws (18); side plate (17); mainspring (34); rebound-lever pin (12); rebound lever (11); hand (10) and trigger (32); hammer (26); cylinder-bolt screw (9); cylinder bolt (7); cylinder-bolt spring (8): latch pin (20); safety lever (3); and safety (30).

The crane and cylinder should not be further dismounted or recoil plate removed except at ordnance depots. The crane and cylinder are dismounted as follows: (a) Unscrew ejector (16) from ejector rod (14), right-handed thread; (b) remove cylinder (22) from crane arbor; (c) unscrew ejector-rod head (13) from ejector rod (NUMBER?), (d) unscrew crane bushing (4), right-handed thread; (e) remove ejector rod (14) and spring (15). To assemble, reverse the above order.

Caution.

In order that the trigger will return to its normal or firing position after each pull on the same, the pressure or grip on the trigger should be entirely released after each discharge.

Failure to observe this caution may result in temporary blocking

of the trigger due to the fact that the trigger must, after discharge, move to its normal or firing position in order that the cylinder bolt may be released from the cylinder when pressure is applied to the trigger, leaving the cylinder free to revolve under action of the hand.

PARTS ISSUED FOR REPAIRS

To Ordnance Officers of Posts and Regiments.

For making repairs to these revolvers in the hands of troops in field and garrison the following spare parts are issued to ordnance officers of posts and regiments. The number opposite each part is the maximum for 100 revolvers, which has by experience been found necessary for ordinary repairs per year. Repairs involving the replacement of parts other than these can only be properly made a depots by expert workmen with the proper tools.

Name of component parts.

Crane lock (Number) 5

Crane-lock screw 10

Cylinder bolt 5

Cylinder-bolt screw 10

Cylinder-bolt spring 10

Ejector-rod head 10

Hammer with strut, strut pin, and strut spring assembled 5

Hammerstirrup 5

Hammer-stirrup pin 5

Hammor-strut spring 10

Latch pin 5

Latch spring 10

Mainspring 8

Rebound lever 5

Side-plate screws 20

Safety 5

Safety lever 5

Stock, right [1] 10

Stock; left [1] 10

Stock screw 5

Trigger (includes safety-lever pin) 10

Appendage: Screw driver 20

[1] Includes escutcheons, plain and threaded.

To Ordnance Depots.

In addition to the above, the following parts and special gauges and tools are issued to ordnance depots:

Crane bushing.

Cylinder, ejector, and ejector rod assembled.

Ejector rod.

Ejector spring.

Gauge for space between cylinder and barrel.

Hammer pin.

Hand.

Punch, set, and block for replacing recoil plates.

Range rod for testing alignment of the barrel and chambers of cylinder.

Rebound-lever pin.

Recoil plate.

Set to upset rod in ratchet.

Stock pin.

Trigger pin.

In removing or replacing a hand in a revolver, lift rebound lever by inserting screw driver between it and frame, so as to free it from lug on hand, and it is important that it be so adjusted that the upward movement of the hand will not begin to revolve the cylinder before the trigger withdraws the cylinder bolt. To insure this it may be necessary to file the hand slightly at the end which first encages the ratchet, and, as this may bring the two points of he hand which engage the teeth of the ratchet too near together, the lower projection may also have to be slightly filed. The length and thickness of this lower projection must be adjusted so as to bring the cylinder in proper position for fixing. This can be done only by expert workmen at the factory.

PARTS NOT ISSUED

The following parts are not issued:

Barrel.

Crane.

Cylinder without ejector and ejector rod.

Ejector without cylinder.

Frame.

Latch.

Side plate.

Sight.

In the case of breakage or injury, disabling the revolver, to parts other than those that may be issued for repairs as designated, either separately or assembled, the revolver must be returned to an arsenal for repairs.

IMPORTANT POINTS

(1) The revolver should be kept clean, free from rust, and properly oiled. The oil should not be used in excess. Waste oil left in the mechanism will cause the parts to gum and work stiffly.

(2) The lock mechanism must not be tampered with. The side plate should not be removed except under the supervision of a noncommissioned officer.

(3) Never attempt to remove the side plate by prying it out of place. It should be jarred out of place by smart blows struck with a piece of wood on the left side of the frame where it is covered by the stock.

(4) The side plate must be replaced from the rear so as to put pin stud in the proper position, care being taken that the latch is drawn back, the latch pin forward and its stud upright, so that it may enter the hole in latch without forcing. See that the latch spring is in its proper position in rear of latch.

(5) The crane and cylinder must not be dismounted unless suitable tools are available, and not then unless absolutely necessary

(6) Never attempt to open the cylinder when the hammer is cocked.

(7) Never attempt to cock the hammer until the cylinder is fully dosed and locked in the frame.

DIMENSIONS

Weight pounds..2, ounces..7

Total length: inches. 10.8

Barrel: Length do 5.5

Diameter of bore do .445

Rifling, number of grooves 6

Groves:

Width inches.. .165

Depth do.... .0035

Twist, one turn in do.... 16

Length do...1 625

Diameter do 1. 695

Chambers:

Number 6

maximum.. inches.. .4873

Diameters (maximum inches .. .4873, minimum do .. .4803

Front sight above axis of bore do .697

EXTERIOR BALLISTICS

1. Rapidity of Fire.

This pistol can be fired I8 times in thirty-eight and two-fifths seconds, loading each chamber separately, and beginning and ending with cylinder closed and chamber empty.

Firing at 25 yards' distance at the figure of a man, and using the pistol as a self-cocker, loading each chamber separately I8 shots have been fired m one minute and ten and three-fifths seconds, making 15 hits, starting and finishing with the cylinder closed and the chamber empty.

Firing at the same figure at 25 yards, loading each chamber separately and using the pistol in “single action”, 18 shots have been fired in one minute and fifteen seconds, making 16 hits, starting with cylinder closed and chamber empty.

2. Accuracy with Fixed Rest

Range 25, 50, 75 (yards)

Mean radius 1.058, 2.042, 2.61 (inches)

Mean vertical deviation 0.692, 1.724, 1.681 (inches)

The above figures represent the mean variations for a great number of targets. Targets with 50 per cent less variations have been made.

3. Drift.

The drift or deviation due to the rifling is, in this arm, to the left, but is more than neutralized by the pull of the trigger when the pistol is fired from the right hand. The drift is slight at short ranges and that for long ranges is immaterial, inasmuch as the pistol is

short-range weapon.

4. Velocity with Striking Energy.

Range. (yards) 0, 25, 50, 75, 100, 125, 150, 175, 200

Velocity. (feet per second) 738.0, 687.4, 651.3, 617.8, 585.7, 555.4, 526.5, 499.0, 473.1

Energy. (foot-pounds) 297.3, 257.85, 231.48, 208.28, 187.20, 168.33, 151.27, 135.88, 121.25

5. Penetration in White Pine.

Range in yards 25 50 75 100 150 200

Depth in inches 3.45 3.38 3.22 3.15 3.00 2.18

A penetration of 1 inch in white pine corresponds to a dangerous wound.

The penetration in moist loam at 25 yards is 19.2 inches.

The penetration in dry sand at 25 yards is 8.28 inches.

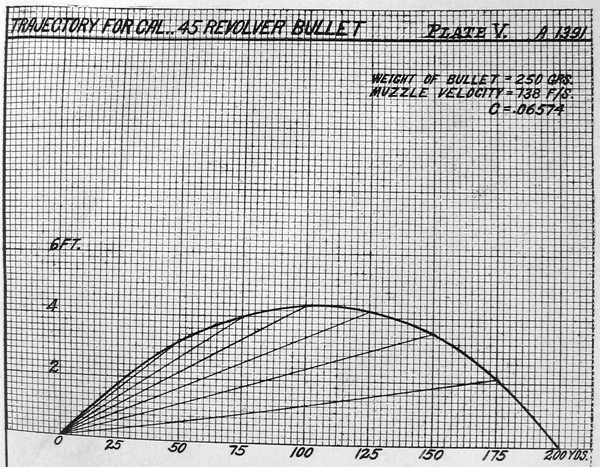

Plate IV.

Plate IV shows the trajectory, with ammunition model of 1909, up to 200 yards. The maximum ordinate for this range is 4.16 feet. The trajectory is very flat up to 75 yards, at which range the revolver is accurate. A close approximation to the maximum ordinate for any range may be obtained by multiplying the square of the range in yards by .000144, the result being the approximate ordinate in feet.

AMMUNITION FOR COLT'S DOUBLE-ACTION REVOLVER, CALIBER .45 MODEL OF 1909

BALL CARTRIDGE.

The components of the ball cartridge consists of cartridge case primer, powder, and bullet.

Cartridge Case.

The cartridge case is cylindrical, and is made of brass. It is provided with a cannelure to prevent the bullet being forced down on the powder.

Primer.

The primer consists of a cup which contains the primer composition, a paper disk, and an anvil which resists the blow of the firing pin. The anvil is provided with two vents, by which the flame is communicated to the charge. Ignition is produced by crushing the composition between the cup and anvil by a blow of the firing pin.

Powder.

The powder used is the K. S. Q., a smokeless powder. The charge varies with the kind and lot, but it is generally about 8.4 grains.

Bullet.

The body of the bullet is a cylinder having two rectangular cannetures containing the lubricant, and the point is a truncated ogive. There is a recess in the base, by which the bullet is brought to proper weight without change of exterior form.

Inches.

Length of bullet 0.735_

Diameter of cylindrical part of bullet .4575

Total length of cartridge 1.575

The bullet is lubricated with Japan wax, and is sealed in the case below the cannelures so as to entirely cover the lubricant and protect it. To render the cartridge waterproof, the case is tightly crimped around the bullet, and the primer is shellacked.

Packing.

The cartridges are packed in pasteboard boxes containing 20 cartridges each. One hundred pasteboard boxes, or 2,000 cartridges, are packed in one zinc case, hermetically sealed, with handle for tearing open. The whole is inclosed in a wooden box, the cover of which is fastened with screw hooks and thumb nuts, and sealed.

Weight of 100 cartridges (pounds) 5

Weight of 2,000 cartridges, packed (pounds) 120

BLANK CARTRIDGE.

This cartridge has the same case and primer as the ball cartridge. There is no bullet. A charge of 9 grains E. C. powder is pressed in the case and held there by a cup of shellacked paper, then a second cup is inserted about 0.16 of an inch from the mouth, and this cup is shellacked after the end of the case is crimped over. Between the first and second cups is an air space which is about 0.4 of an inch long.

These cartridges are packed in a manner similar to the ball cartridges. The packing-box cover has not the quick-opening screw-hook and thumb-nut fastening. A box of 2,000 cartridges weighs 48 pounds.

Blank Cartridge (Present Design).

The blank cartridge as manufactured since March, 1910, differs from the original blank with two paper cups in that only one cup is used, and the case is bottle-necked and closed the same as the caliber .30, model of 1909, blank. A charge of 3.5 grains of E. C. powder is used. A box of 2,000 of these cartridges weighs 38 pounds.

WAR DEPARTMENT,

OFFICE OP THE CHIEF OP ORDNANCE,

Washington, June SO, 1913.

September 10,1909.

Revised June 30,1913.

FORM No. 1927.

Ed. June 13-17 - 10,000